If you dive Nitrox, it’s vital you not only know what is in your cylinder but also how it got there. Unfortunately, this seems to mystify many Nitrox divers. This lack of understanding can lead to costly mistakes.

In this article, we’ll examine the many possible ways to make Nitrox and how this affects where and how you fill your Nitrox cylinders.

Nitrox the old-fashioned way

In the early days of Nitrox diving, you could only create Nitrox by partial pressure blending. What is that?

- You start by partially filling a cylinder with a certain amount of oxygen. How much oxygen will depend on factors such as the desired oxygen concentration and the cylinder’s final fill pressure.

- You next fill the cylinder the rest of the way with air.

- After filling the cylinder, you analyze its contents to see whether you were within spitting distance of the desired Fraction of Oxygen or FO2.

Partial pressure blending was time-consuming and labor-intensive. Worse, it comes with the risk of fire or explosion. Why is that?

- The air we usually use to fill cylinders contains minute quantities of hydrocarbons and other contaminants. These can build up on the inside surfaces of cylinders and valves.

- When exposed to air, this hydrocarbon buildup poses little risk. However, these contaminants can spontaneously combust if exposed to pure oxygen under pressure.

To minimize the risk of fire and explosion, cylinders being filled by partial pressure blending must be oxygen clean. What constitutes oxygen cleanliness varies by application. However, in scuba diving, it means:

- The cylinder and valve have been thoroughly cleaned with a special solution designed to remove all traces of dirt, grease, hydrocarbons and other contaminants.

- Any neoprene O-rings are replaced with ones made with Viton™ or a similar material that resists oxidation.

- Valve components are reassembled using Christo lube or a similar noncombustible lubricant.

At this point, the cylinder and valve are considered O2-clean and can be filled using partial pressure blending. However, to maintain its O2-clean status, the cylinder can only be filled with oxygen and oxygen-compatible air.

What is oxygen -compatible air? It is air that has been filtered to a much higher standard than normal scuba air and, as such, is far less likely to cause hydrocarbon contamination.

Obviously, the hassle of establishing and maintaining O2 cleanliness in cylinders and the time and labor needed to dispense Nitrox using partial pressure blending means that doing so was not a viable option for most dive centers and their customers.

There had to be a better way. And there was. In fact, there are several more viable options for creating Nitrox than doing it the old-fashioned way. And as the popularity of Nitrox exploded during the mid-1990s, these ways became increasingly important.

40: The magic number

When it comes to creating Nitrox, the number 40 is significant. Why? Because as long as a cylinder, valve or any other equipment will not be exposed to a gas mixture with an oxygen content greater than 40 percent, it does not need to be O2 clean.

So, if you can create Nitrox in such a way that the end users’ cylinders will not be exposed to an oxygen concentration greater than 40 percent, you can eliminate the drawbacks associated with partial pressure blending. Let’s take a look at three ways to do just that.

Nitrox cascade

This is perhaps the simplest approach to creating premixed Nitrox. It involves manifolding several larger storage cylinders together and treating them as one large Nitrox cylinder. You then partial pressure blend the desired Nitrox mix inside the storage cylinders.

Once you’ve created a Nitrox blend of up to EAN40, you can use it to fill customers’ Nitrox cylinders by treating the bottles as a cascade. Because customers’ cylinders will never be exposed to oxygen concentrations greater than 40 percent, they do not need to be O2 clean.

The limitation of this system is that, like partial pressure blending in customers’ cylinders, it can be labor-intensive and time-consuming. However, it is among the most affordable approaches to creating premixed Nitrox.

Mixing stick

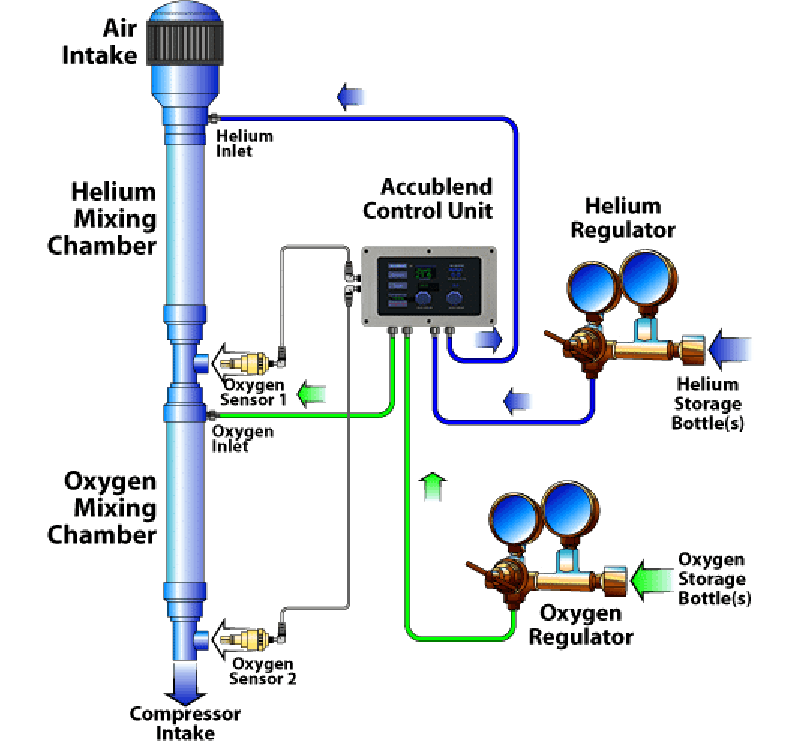

Nitrox mixing sticks appeared in the late 1990s and quickly became the most popular way to create premixed Nitrox. A Nitrox stick is a PVC tube attached to a compressor’s air intake.

- Air enters at the top, usually passing through a filter to do so.

- Partway down the tube is an oxygen inlet, connected to an oxygen storage cylinder.

- Inside the tube are baffles designed to ensure thorough mixing of air and oxygen.

- At the bottom of the tube is a port to plug in an oxygen analyzer. This allows the operator to continuously monitor the FO2 of the resulting mix.

Initially, an operator had to be present during the blending process to adjust the oxygen flow as needed. Today there are automated systems available that will do this for you. The result is a cost-effective way to create and store large quantities of premixed Nitrox.

Membrane system

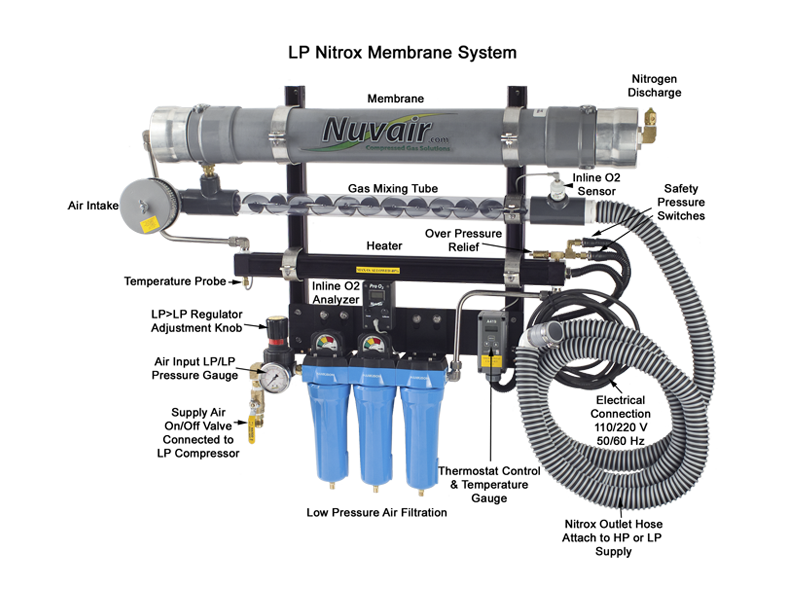

A membrane system consists of a compressor and a membrane. The membrane is designed to remove a portion of the nitrogen that passes through the system, resulting in a gas mixture with a higher concentration of oxygen.

Membrane systems can be finicky and may require a lot of maintenance. However, they require no external oxygen cylinders. This makes them an ideal system for liveaboard dive vessels.

How Blue Grotto creates Nitrox

Blue Grotto has a membrane system and a single large Nitrox storage cylinder. We fill the storage cylinder with EAN40, then mix it with air in customers’ cylinders to achieve the desired oxygen concentration. Because nothing in the system is exposed to oxygen concentrations greater than 40 percent, customer cylinders do not need to be O2 clean.

Most of our staff are certified Nitrox blenders. We carry an app on our phones that lets us quickly determine how much EAN40 to mix with air to get the desired FO2 value. The entire process takes little more time than filling a tank with plain air.

Knowing where is essential

Over time, we’ve learned that a surprising number of divers don’t know where their Nitrox comes from. This is critical if someone has a cylinder that has been O2 cleaned and they are trying to maintain its O2 service rating.

We mentioned earlier that membrane systems are finicky. Ours is no exception. Occasionally, it will be out of service while we fix yet another issue.

When this happens, people will come to us for Nitrox fills. We will explain that our system is temporarily down, but we can still fill their tanks with air. “Oh, no,” they will tell us. “Mine is a Nitrox cylinder. It can only be filled with Nitrox.” That’s not entirely accurate.

What these divers should be telling us is whether or not their cylinder has been O2 cleaned. If it has and the cylinder’s owner wants to maintain its O2 service rating, it can only be filled with oxygen-compatible air.

Does Blue Grotto’s system dispense oxygen-compatible air? No, it doesn’t. Remember, our system is never exposed to oxygen concentrations greater than 40 percent. As a result, our air doesn’t need to be oxygen compatible.

Fortunately, dive centers that still create Nitrox using partial pressure blending are becoming increasingly rare. Most dive centers in this part of the country dispense premixed Nitrox. Thus, oxygen compatibility is moot.

But it leads to another critical question. That is, if your cylinder has been oxygen cleaned, do you know with absolute certainty that it has been filled solely with oxygen-compatible air?

This is something of which too many Nitrox users seem blissfully unaware. Particularly those whose cylinders are ostensibly O2 clean. They assume that, so long as their tank has only been filled with Nitrox, it remains O2 service rated. But if it has been filled even once with premixed Nitrox, there is a good possibility that Nitrox was not created with oxygen-compatible air. Which means their tank is no longer O2 clean.

Recommendations

Here are some common recommendations for Nitrox users.

- If possible, get your Nitrox from dive centers that dispense premixed Nitrox. This will save you the time and expense of O2 cleaning and the additional hassles of maintaining your tanks’ O2 service rating.

- If you do have O2 clean cylinders, don’t assume that every dive center that dispenses Nitrox creates that Nitrox using oxygen-compatible air. Many, if not most, do not.

- Don’t assume that just because a cylinder has a green-and-yellow Nitrox decal, it contains EAN32. Always analyze your cylinders before use and label the contents clearly.

- Don’t rely on others to analyze your cylinders for you. Invest in your own O2 analyzer and make sure you know how to use it correctly. Regularly compare its accuracy against other analyzers.

- Simply knowing your cylinder’s oxygen concentration is not enough. Knowing the Maximum Operating Depth (MOD) associated with the FO2 is more important. You can download an MOD table using the link at the bottom of the page.

- Avoid those tiny, hard-to-read contents labels sold by training agencies and others. Colored duct tape and permanent markers will help ensure you can clearly read essential values such as FO2 and MOD.

If you have questions about any aspect of Nitrox use, feel free to ask us.